tel:+86 137-5138-0975

tel:+86 137-5138-0975

tel:+86 137-5138-0975

tel:+86 137-5138-0975

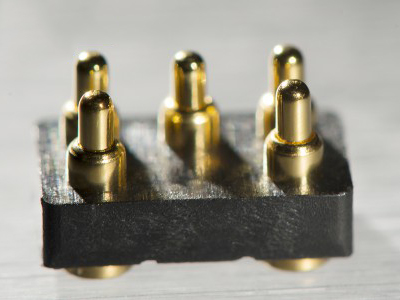

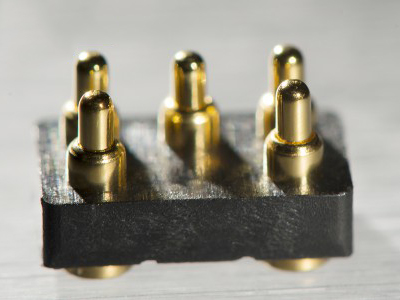

pogo pin is a precision connector used in mobile phones and other electronic products, widely used in In semiconductor equipment, it plays a role in connection. There are different appearances according to different applications, but the overall pogo pin There is a precision spring structure inside. The surface of the product is generally gold-plated, and the spring should also be gold-plated when the process is required. Pogo pin connector contact piece end design and form requirements:

1. Design requirements for the end of the contact

is a non-standard type of contact. It is designed according to the cable requirements of the whole machine. First, it is necessary to confirm the size of the plug-in end, the product installation method, the appearance form and the cable specification. In the case that it is difficult to confirm the cable, design the wiring hole according to the contact number. The wiring hole can meet the needs of large wire gauge wires. The ratio of the diameter of the wire core to the inner diameter of the welding cup is generally 0.5-0.7; When connecting a wire, the design principle is that the diameter of the cable core and the connection hole of the contact is appropriate, and the ratio of the diameter of the wire core to the inner diameter of the welding hole is generally 0.6-0.8.

2, the form of the end of the contact is required

in pogo In the pin connector, the contact piece is an indispensable part of the connector, and its main function is to be responsible for signal transmission. In the design process of the connector, the contact is composed of the mating end and the tail end. The mating end is generally composed of elastic parts and rigid parts to ensure the reliability of the contact between the connector plug and the socket; the tail end of the contact is responsible for the cable connection between the equipment, the interconnection between the printed boards or The interconnection between the cable and the board is used in the connection of the cable. The terminal end of the connector can be divided into four types: welding wire type, crimping wire type, insulation piercing type, and solderless winding type; application On the printed circuit board, the contact termination forms can be divided into four types: straight welding, bending welding, surface mount and solderless press-in type.