tel:+86 137-5138-0975

tel:+86 137-5138-0975

tel:+86 137-5138-0975

tel:+86 137-5138-0975

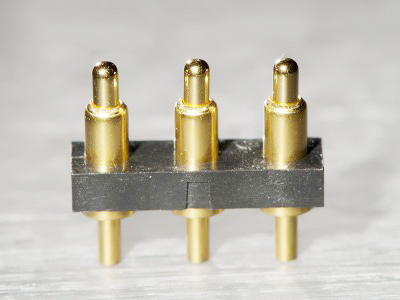

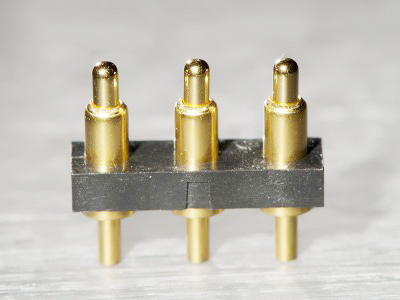

Pogopin, also called pogo pin, English name pogo pin; it is a kind of application used in mobile phones, etc. Precision connectors in electronic products are widely used in semiconductor equipment to play a role in connection.

There are different appearances according to different applications, but as a whole, there is a precision spring structure inside the pogo pin. The surface of the product is generally gold-plated, and the unit price of the product is generally about 5 to 1 yuan; Pogo pin is a spring-type probe formed by the three basic components of needle shaft, spring, and needle tube after being riveted and preloaded by precision instruments. There is a precise spring structure. The surface coating of pogo pin is generally gold-plated, which can better improve its anti-corrosion function, mechanical performance, electrical performance, etc. The needle tip has a sharp needle, a grasping needle, a round needle, a knife needle, etc. Pogo pins are generally used for precision connections in electronic products such as mobile phones, communications, automobiles, medical, aerospace, etc., which can improve the corrosion resistance, stability, and durability of these connectors.

Pogo pins have been applied to various components in life, so how to make pogo pins and what is the production process?

1. Pogo pin processing: the most advanced and confidential machine tools are used to process pogo pins, and the processed parts must meet quality standards.

2. Pogo pin electroplating: This is also a very important part, to ensure that the gold plating layer in the hole is good, without blackening, different color and poor plating.

3. Pogo pin quality inspection: After the processing is completed, the quality department will check each pogo pin pogo pin to see if there is any difference in appearance and whether the spring has elasticity, etc.

4. Batch inspection and shipment: Before shipment, a batch of qualified products will be selected for testing, and will be shipped only after there are no problems in the testing.