tel:+86 137-5138-0975

tel:+86 137-5138-0975

tel:+86 137-5138-0975

tel:+86 137-5138-0975

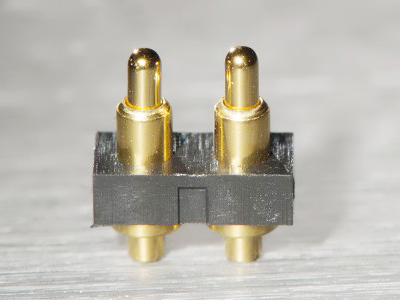

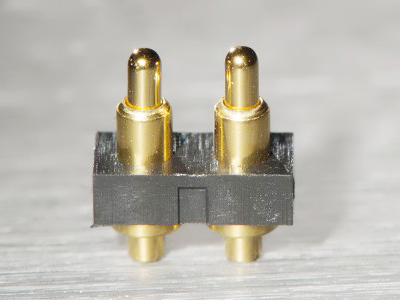

As a connection device commonly used in high-demand electronic products such as mobile phones and wearable devices——Pogo PinPogo Pin a>The connector plays an important role in connection and intercommunication; today I will simply analyze the structure of the pogo pin connector;

pogo pin is composed of three parts: needle, needle tube, and spring.

1. Needle: There are three options for pogo pin needles.

The material of the pogopin pogopin needle and needle tube is generally brass, and copper is a very active metal. It will react with oxygen in the air when exposed to the air, and the surface will oxidize. Therefore, pogopin spring needles must be electroplated on the surface; the more commonly used is generally gold-plated on the surface, and some require nickel plating, zinc plating, silver plating or plating. Today we will talk about some of the problems that pogopin spring needles will encounter during the gilding process.

The gold plating process occupies an obvious important position in pogopin pogo pin electroplating. At present, except for some strip pogo pins using selective gold electroplating process, the gold plating in the hole of a large number of pinhole parts still uses barrel plating and vibration Plating to proceed. In recent years, the size of the connector has become more and more miniaturized. The quality of the gold plating in the pinhole parts has become more and more prominent. Users have higher and higher requirements for the quality of the gold layer. Some users are concerned about the appearance of the gold layer. Even to a very critical level, in order to ensure the quality of the gold-plated layer of the connector, these common quality problems are always the key to improving the quality of the gold-plated connector. The following is a discussion of the reasons for these quality problems.

1. The color of the gold-plated pogo pin is not normal

The color of the gold plating layer of the pogo pin is inconsistent with the normal color of the gold layer, or the color of the gold layer of different parts in the same accessory product is different. This is one of the most common electroplating problems.

2. The influence of the impurity of the gold-plated raw material of the pogo pin

When the impurities introduced by the chemical materials added to the plating solution exceed the tolerance of the gold plating solution, it will quickly affect the color and brightness of the gold layer. If it is affected by organic impurities, the gold layer will become dark and bloom. Erchow test piece to check the darkening and blooming position is not fixed. If metal impurities interfere, the effective range of the current density will be narrowed. The Haul tank test shows that the current density of the test piece is not bright at the low end or the high end is not bright and the low end is not plated. It is reflected that the plating layer on the plated parts is red or even Black, the color change in the hole is more obvious.

3. The gold plating current density of the pogo pin is too large

Due to the calculation error of the total area of the parts of the plating tank, the value is larger than the actual surface area, so that the gold plating current is too large, or the amplitude is too small when vibrating gold plating, so that all or part of the plating parts in the tank are crystallized coarsely. The gold layer was reddened visually.